Utility Vans – The Hammer or the One Who Swings It?

Utility Vans – The Hammer or the One Who Swings It?

When it comes to getting the job done, some tools are just tools. But a utility van is different. It can be a blunt-force implement in your fleet… or the precise extension of your will. The difference lies in how it’s configured, how it's used, and whether it’s working for you—or you're working around shortcomings.

Often referred to as an enclosed utility van or enclosed service van, these vehicles are prized for the protective shell they offer—securing tools, materials, and equipment from theft, weather, and jobsite chaos. More than a cargo hold, the van’s interior becomes a mobile workspace. In the trades, organization isn’t just convenience—it’s profitability. And an intelligently enclosed environment is where efficiency starts earning its keep. Whether you're running a plumbing business, operating a well digging truck, or managing electrical service crews, the right setup makes all the difference in productivity.

This guide breaks down the features that define a van’s role in your operation, from roof height and compartments to upfits and advertising space. Because in the trades, every inch of steel, every bolt-on rack, every plug and panel determines whether you're simply hauling gear or maximizing your momentum.

Chassis Options for Utility Vans

The chassis is the backbone of any utility van—and the starting point for tailoring performance to your business needs. From engine type to drivetrain, the right configuration ensures your van can carry the load, handle your terrain, and minimize costly downtime. Whether you're running a single van or managing a growing fleet, these choices have lasting impacts on total cost of ownership and operational flexibility.

- Fuel Type (Gas vs. Diesel): The choice of fuel affects power delivery, operating costs, and long-term maintenance. Gas engines often offer lower upfront costs and simpler servicing, while diesel engines provide torque-rich performance and improved fuel efficiency for longer hauls and heavier loads.

- Engine Size: A properly sized engine ensures your van can meet your payload demands without sacrificing fuel economy. Too small, and you’ll overburden the powertrain; too large, and you're paying for unused horsepower. Consider daily routes, typical load weight, and idle time.

- Class Rating (Payload & Towing Capacity): Utility vans span a wide range of weight classes, each with distinct capabilities and regulatory considerations. Choosing the right class ensures your van can safely handle the demands of your trade.

- Class 2 & 3: With a Gross Vehicle Weight Rating (GVWR) up to 14,000 lbs, these are the most commonly used vans in service trades like plumbing or telecom; they offer maneuverability and cost significantly less than heavier classes.

- Class 4 & 5: Ranging from 14,001 to 19,500 lbs GVWR, these vans strike a balance between high capacity and versatility. They’re well-suited for industrial contractors who need to haul heavier tools, tow equipment, or carry larger crews.

- Class 6 & 7: With GVWRs ranging from 19,501 to 33,000 lbs, these vans are designed for demanding commercial applications, such as utility fleets, municipal services, or specialty trades that require high payloads and advanced upfits. Vehicles in this range may require a Commercial Driver's License (CDL), depending on the configuration and local regulations.

- Drivetrain (4x2 vs. 4x4)

- 2WD, 4x2, RWD, FWD - For fleets operating in urban centers or mild climates, 4x2 delivers efficiency and simplicity.

- 4WD, 4x4, AWD - If your routes include job sites with loose gravel, snow, or mud, a 4x4 setup offers the traction and control needed to stay productive in all conditions.

- Wheelbase: Your wheelbase dictates more than turning radius—it determines how much upfit space you’ll have to work with. A longer wheelbase can accommodate more shelving and equipment, while a shorter one improves maneuverability in tight environments, like city streets.

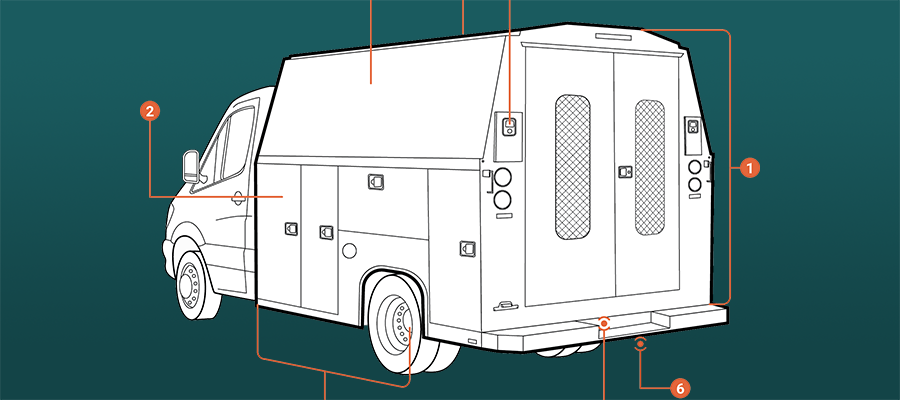

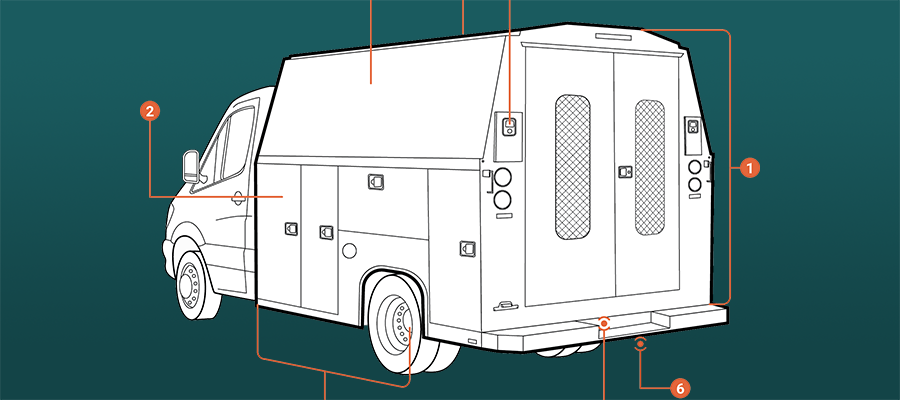

Body Options

The body of a utility van is more than just an enclosure—it’s a workspace, a storage system, and a mobile brand presence. From roof height to integrated compartments and exterior graphics, these features directly affect team efficiency, crew comfort, and your customer-facing image. A well-matched body configuration ensures the van aligns with your trade, crew size, and daily operations.

- Roof Height: Choosing between low, medium, or high-roof configurations means balancing headroom, function, and cost. High-roof vans offer full stand-up access—ideal for mobile workshops or repetitive loading, but often come with a higher price tag. Low roofs improve fuel efficiency and ease of access in tight spaces. Match roof height to your job site conditions, workflow needs, and budget tolerance.

- Exterior Compartments: Utility vans come standard with body-integrated exterior compartments, designed for secure and organized storage. Look for models with watertight seals, keyed locks, and compartment interiors outfitted with shelves or drawers. Efficient layout means quicker access, better protection, and fewer wasted steps on the job.

- Advertising Space: The broad, uninterrupted paneling above the exterior compartments is prime real estate for mobile branding. From bold vinyl wraps to clean-cut door decals, your van doubles as a rolling advertisement. Branded graphics boost visibility, enhance professionalism, and turn every drive into a marketing opportunity.

Upfit Options

The right upfits turn a utility van into a job-specific solution. Whether you're hauling conduit, securing ladders, or towing a trailer, these additions have a direct impact on safety, efficiency, and day-to-day usability. The right upfits maximize productivity, protect your gear, and help your crew work smarter—not harder.

Conduit Carrier: Designed for long, fragile materials like conduit, pipe, or trim stock, these exterior-mounted tubes are a must-have for trades that rely on clean, unbent inventory. Lockable and weather-sealed, they free up interior space while keeping materials protected and accessible.

Ladder Rack: Ladder racks come in several configurations, each designed to balance accessibility, security, and vehicle compatibility.

- Drop-Down Racks use manual or hydraulic mechanisms to lower ladders to a reachable height—ideal for high-roof vans and crews prioritizing safety and ergonomics.

- Crossbar/Cargo Racks are simple, fixed bars that ladders and longer materials strap onto—cost-effective and great for low-roof vans or lighter-duty use.

- Clamp & Lock Racks offer fast, strap-free loading with built-in locking systems—perfect for service techs making frequent stops.

- Interior Racks mount ladders inside the van, protecting them from weather and theft—especially useful in urban or high-theft areas.

Shelving Systems: From adjustable metal shelves to modular drawer units, the right interior upfit keeps tools, parts, and materials secure and accessible. Options range from open shelving for quick access to enclosed systems that protect sensitive gear. Custom configurations tailored to your trade can significantly reduce search time and enhance job site efficiency.

Cab Partition (Bulkhead): A cab partition creates a solid barrier between the driver and cargo area, enhancing safety, comfort, and climate control. Available in steel, aluminum, or composite materials, partitions help prevent shifting loads from entering the cab during sudden stops. Many designs are contoured to preserve seat travel and reduce noise, while also improving HVAC efficiency by isolating the cab from the cargo bay.

Tow Hitch: A tow hitch expands your van’s capability for hauling trailers, generators, or secondary storage. From Class I for light-duty needs to Class IV or V for heavy commercial loads, selecting the right hitch ensures safe operation and prevents chassis strain. Be sure to factor in tongue weight and total payload.

Trailer Plug: Connectivity counts when towing. Common plug types like 4-pin or 7-blade configurations vary in complexity—from basic lighting to integrated brake controls. Durable housings and corrosion-resistant contacts are a must for fleets operating in rough weather or frequent stop-start cycles.

Summary

Selecting the right utility van setup is more than a purchase decision—it’s a strategic investment in your business. From chassis specifications and body configurations to job-specific upfits, every detail affects your team’s efficiency, safety, and brand presence. Whether you're outfitting a single vehicle or scaling a fleet, leveraging the expertise of your commercial vehicle dealer will help you align these options with your operational needs, ensuring long-term value, reliability, and performance on the job.

About the author: Ryan E. Day is a communications specialist at Work Truck Solutions, where he turns complex ideas into engaging content that drives business impact across industries and platforms. With 13 years of experience in B2B content marketing, Ryan specializes in storytelling, strategic messaging, and digital optimization.

About the author: Ryan E. Day is a communications specialist at Work Truck Solutions, where he turns complex ideas into engaging content that drives business impact across industries and platforms. With 13 years of experience in B2B content marketing, Ryan specializes in storytelling, strategic messaging, and digital optimization.

Ryan's work has been featured in Comvoy, Quality Digest, Youtube, and Amazon Kindle.

Connect with Ryan on his Linkedin page.

UPDATED ON: JULY 10, 2025

Published on: January 04, 2019